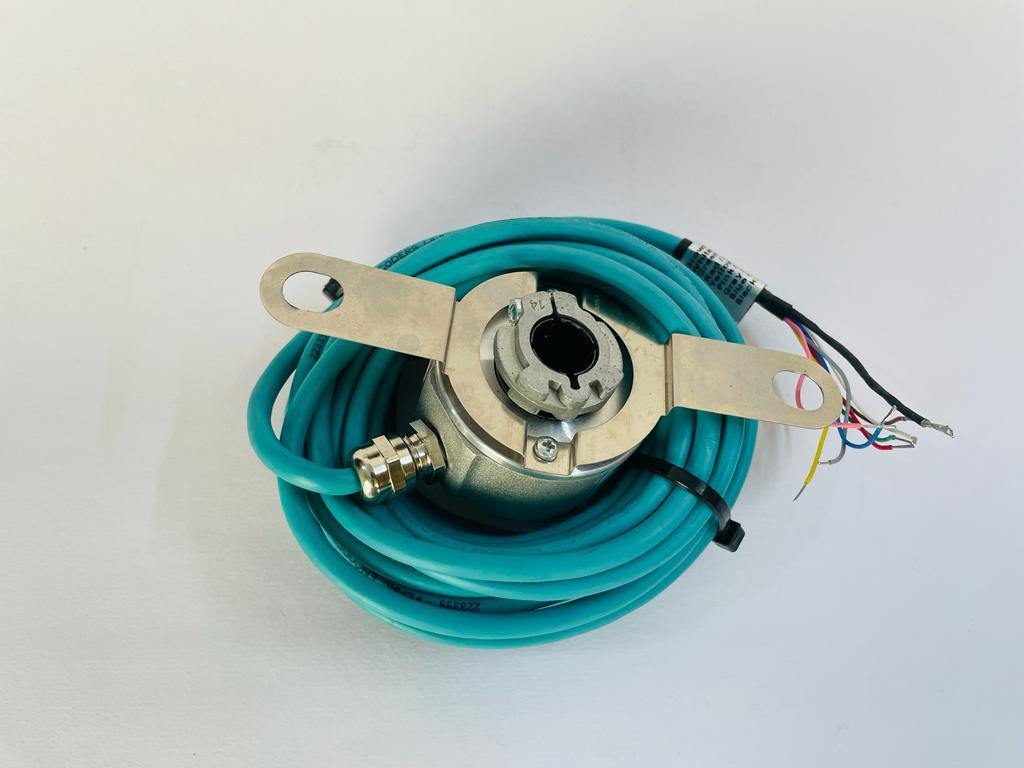

Incremental Encoder

Price 6500.0 INR/ Unit

Incremental Encoder Specification

- Power Supply

- AC

- Operating Temperature

- -20C to +85C Celsius (oC)

- Product Type

- Incremental Encoder

- Application

- Power Electronics

- Usage & Applications

- Automation

- Phase

- Single

- Features

- Durable

Incremental Encoder Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 7 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Incremental Encoder

Fenac is a Turkish company specializing in the design, development, and production of sensors for control and automation applications, with a significant focus on encoders. They offer a wide range of motion control and feedback devices, aiming to provide high-quality, competitive solutions for various industries.

Heres a breakdown of Fenac encoders:

1. Types of Fenac Encoders:

Fenac manufactures both rotary and linear encoders, employing both optical and magnetic technologies. Their product range includes:

- Incremental Encoders: These encoders generate a series of pulses as a shaft rotates or a linear component moves. The number of pulses per revolution (PPR) or per unit of linear displacement determines the resolution. They are commonly used for speed measurement and relative position tracking. Fenac offers:

- Optical Incremental Encoders: Utilize light and a coded disk to generate pulses.

- Magnetic Incremental Encoders: Use magnetic principles for pulse generation, often offering higher robustness in harsh environments.

- Available in various forms: Shafted, hollow shaft (through or end), and conic shaft.

- Absolute Encoders: Unlike incremental encoders, absolute encoders provide a unique position value immediately upon power-up, even after a power interruption. This eliminates the need for a homing sequence. Fenac offers:

- Optical Absolute Encoders.

- Magnetic Absolute Encoders.

- Available in single-turn (position within one revolution) and multi-turn (tracking multiple revolutions) variants.

- Support various interfaces like SSI, BiSS, CANopen, Profinet, EtherCAT, and EtherNet/IP.

- Optical Absolute Encoders.

- Programmable Encoders: These encoders allow users to set parameters like resolution and output characteristics via software or programming tools, offering greater flexibility.

- Heavy Duty Encoders: Designed for robust industrial environments, offering enhanced durability and protection (e.g., IP65).

- Draw Wire Units (Wire Actuated Encoders): These are linear position sensors that use a cable and a spring-loaded spool to measure linear displacement.

- Magnetic Linear Encoders: Directly measure linear movement using magnetic principles.

- Encoders with Analog Outputs: Provide analog signals (e.g., 0-10V or 4-20mA) for position feedback.

- Miniature Encoders: Compact designs for applications with limited space.

- Bearingless Encoders: Designed without internal bearings for specific mounting and application requirements.

- Wheel Encoders: Used with measuring wheels to track linear distance.

2. Key Features and Technology:

Fenac encoders are known for:

- Precision and Accuracy: Offering resolutions up to 25,000 PPR (Pulses Per Revolution) or higher for incremental encoders, and various bit resolutions for absolute encoders.

- Robust Construction: Built with durable mechanical and electrical components, often featuring high IP ratings (e.g., IP65, IP67) for protection against dust and water.

- Wide Operating Temperature Range: Many models can operate effectively in diverse environments, typically from -20C to +85C.

- Versatile Outputs and Interfaces: Supporting a wide range of electrical outputs (e.g., Push-Pull) and communication protocols (SSI, BiSS, CANopen, etc.).

- Various Shaft and Flange Options: Available with different shaft diameters (solid, hollow, through-hollow) and flange sizes to suit diverse mounting requirements.

- CE Compliance: Adhering to European Union safety and performance requirements.

3. Applications:

Fenac encoders are widely used across numerous industries requiring precise motion control and position feedback, including:

- Industrial Automation: General machinery, robotics, packaging machinery, textile machinery, printing machinery.

- Elevator Systems: Ensuring precise cabin positioning and smooth operation.

- CNC Machines: For accurate control of tool paths and positioning.

- Iron and Steel Industry: In processes like rolling, cutting, transformation, and transportation, where high durability and reliability are crucial.

- Machine Tools: For precision movement and feedback.

- Weighscales and Conveyors.

- Medical Equipment.

- Aerospace Equipment.

- Test Equipment.

In essence, Fenac encoders provide reliable and accurate solutions for measuring length, position, speed, and angle in a wide array of industrial and automation settings

FAQs of Incremental Encoder:

Q: What is the operating temperature range of the Incremental Encoder?

A: The operating temperature range of the Incremental Encoder is -20C to +85C.Q: Is the Incremental Encoder suitable for automation applications?

A: Yes, the Incremental Encoder is specifically designed for automation applications.Q: What type of power supply is required for the Incremental Encoder?

A: The Incremental Encoder operates on an AC power supply.Q: Is the Incremental Encoder suitable for use in power electronics?

A: Yes, the Incremental Encoder is ideal for applications in power electronics.Q: How durable is the Incremental Encoder?

A: The Incremental Encoder is designed with durability as a key feature, ensuring reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fenac Encoder Category

Fenac Encoder

Price 6500.0 INR

Minimum Order Quantity : 1

Weight : Approx. 150g

Thickness : Compact

Frequency : 100 kHz max.

Capacity : Depends on Model

|

NCS Automations

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry