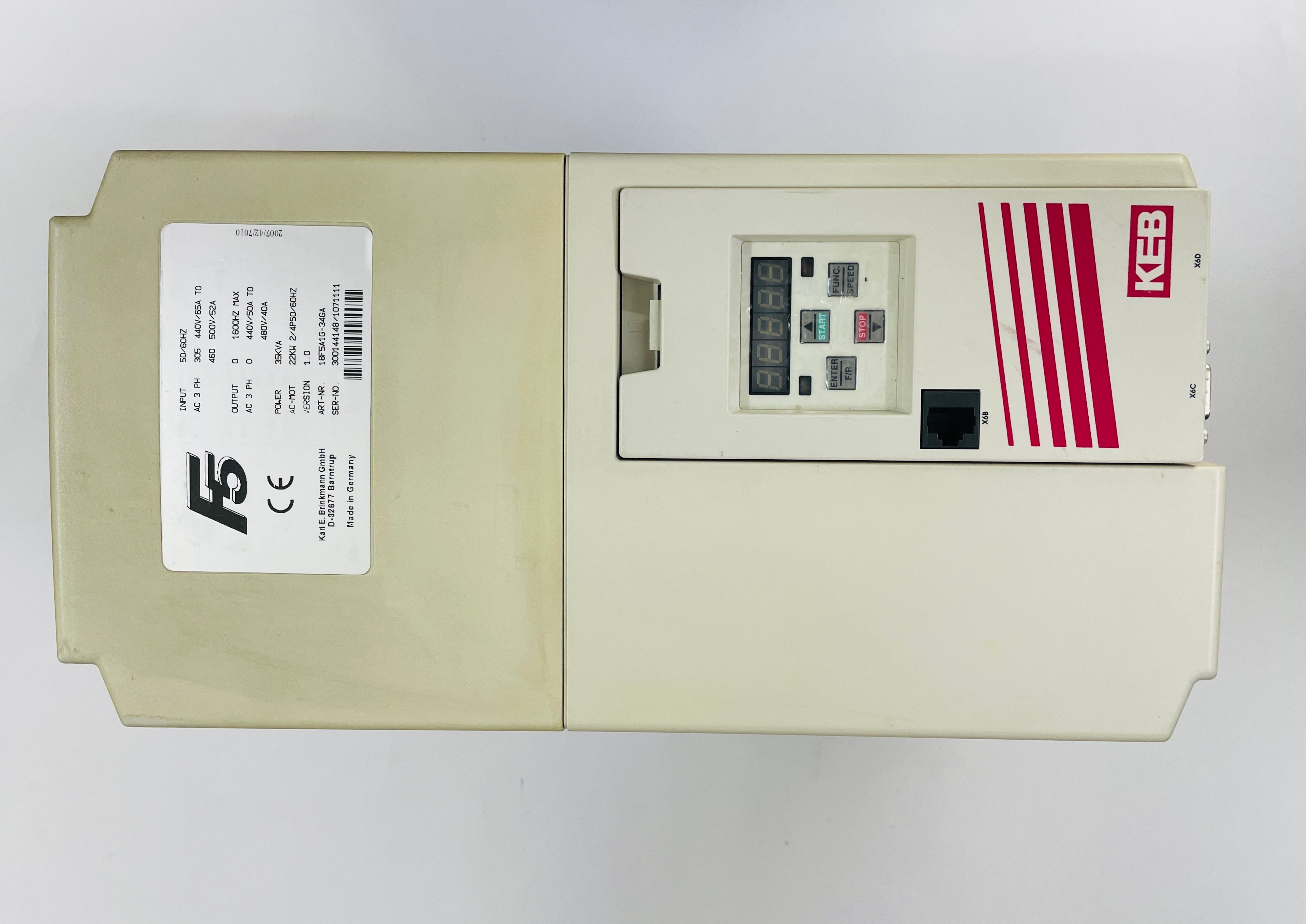

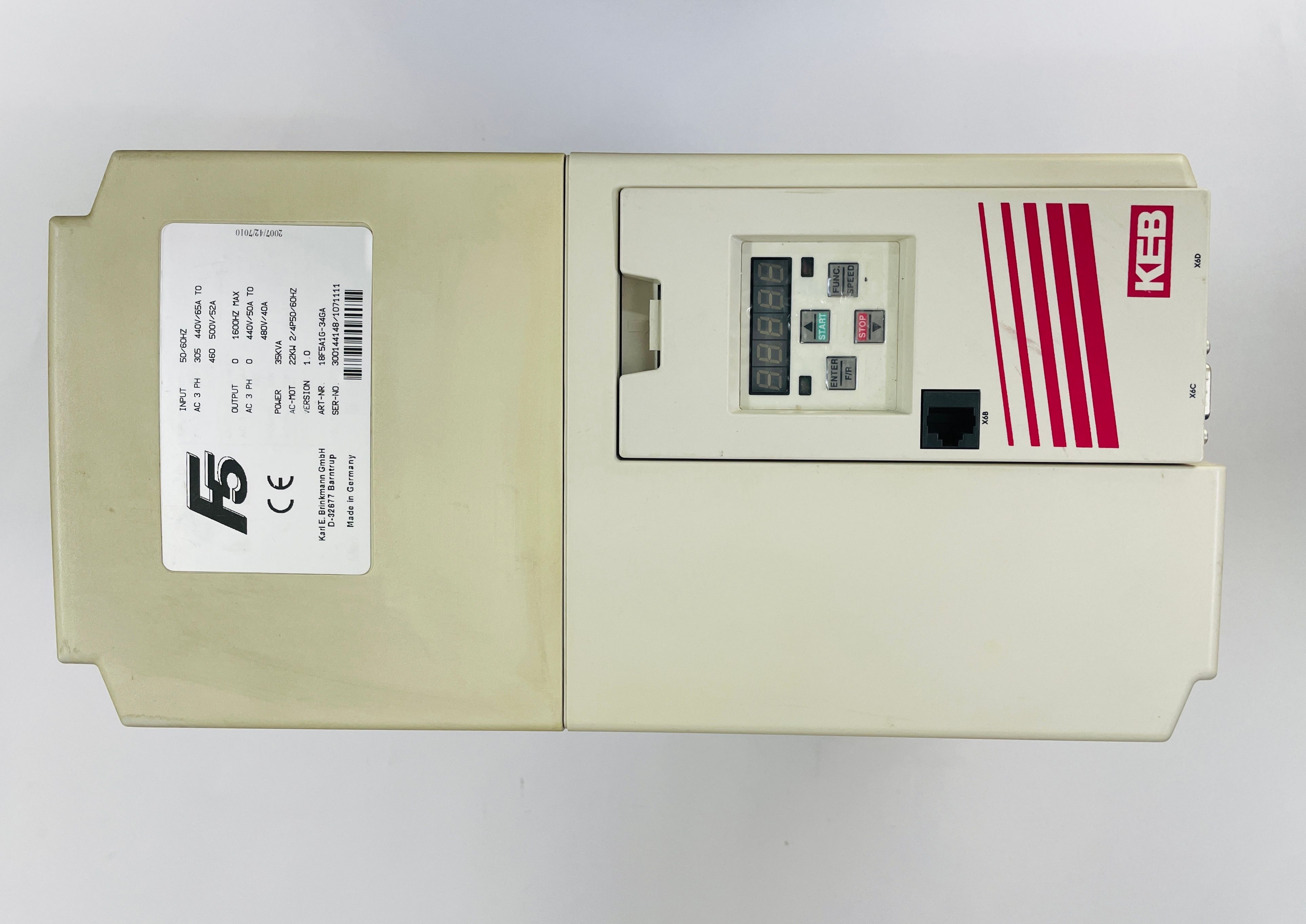

KEB Combivert F5 Series

Price 100000 INR/ Piece

KEB Combivert F5 Series Specification

- Features

- Dynamic braking, vector control, programmable I/O, fieldbus interfaces

- Operating Temperature

- -10C to +40C

- Interface

- RS232/RS485, CANopen, Profibus; programmable digital/analog inputs

- Sensors Specification

- Optional external sensors supported

- Input

- Three-phase, 400V/230V AC

- Display Type

- LED/LCD (depending on model)

- Power Source

- Mains AC

- Power Supply

- AC

- Response Time

- <10 ms

- Output

- Three-phase, variable frequency

- Components

- IGBT power module, cooling fans, connection terminals, control board

- IP Rating

- IP20

- Usage

- Industrial automation

- Product Type

- AC Drive (Frequency Inverter)

- Application

- Pumps, Fans, Conveyor Systems, Mixers, Elevators

- Rated Voltage

- 400V AC

- Supply Voltage

- 230V/400V

- Size

- Model dependent

- Dimension (L*W*H)

- varies by model; e.g., 360mm x 131mm x 230mm

- Function

- Speed control of AC motors

- Color

- Standard (gray/red)

- Weight

- Approx. 3-20 kg (depending on model)

- Current Rating

- Up to 1370A

- Capacity

- 0.37kW to 900kW

- Frequency

- Output frequency: 0...800 Hz, Input: 50/60Hz

- Programming

- Keypad and PC software

- Protection Functions

- Over/under voltage, overcurrent, short-circuit, overtemperature

- Environmental Protection

- Conformal coated boards

- Display Language

- German/English selectable

- EMC Compliance

- Integrated RFI filter

- Overload Capacity

- 200% for 3 seconds

- Braking

- Integrated DC braking, optional brake chopper

- Mounting Type

- Wall mount/DIN rail

- Regenerative Feedback

- Optional (regenerative units available)

- Software Tools

- COMBIVIS (KEB software suite)

- Communication Protocols

- CANopen, Profibus, DeviceNet, EtherCAT (optional)

- Start/Stop Logic

- Programmable digital & analog inputs/outputs

- Control Method

- V/Hz control, Sensorless Vector, Closed Loop Vector

- Cooling Method

- Forced air cooling

- Acceleration/Deceleration Time

- 0.1 to 3600 seconds

About KEB Combivert F5 Series

Versatile Advantage: Trusted for Global Industrial Automation

The KEB Combivert F5 Series is widely used by manufacturers, dealers, exporters, and service providers for its grandiose adaptability. Its primary advantage lies in reliable speed and torque control for applications such as pumps, conveyor systems, mixers, and elevators. Frequently found in industrial plants, warehouses, and commercial complexes, the F5 is the go-to choice for world-class engineering reliability, flexible deployment, and comprehensive protection functions in demanding environments.

Robust Supply and Packaging: Exchange and Ship with Confidence

With a strong supply network, the KEB Combivert F5 Series is shipped promptly across India and globally. Interested parties can request detailed quotations, and sample exchange policies are available for select clients. Each unit is securely packaged to ensure safety during transit, and all packaging details meet export and industrial standards. Dealers, retailers, and distributors benefit from a seamless order process, guaranteeing efficient and reliable supply management.

FAQs of KEB Combivert F5 Series:

Q: How do I program the KEB Combivert F5 Series for custom applications?

A: Programming can be accomplished via the integrated keypad or using the KEB COMBIVIS PC software suite. Both tools provide access to a comprehensive set of parameters for tailoring start/stop logic, speed control, and I/O configurations to your system requirements.Q: What types of industrial environments benefit most from the F5 Series?

A: The F5 Series excels in environments requiring precise speed and torque control, such as manufacturing plants, warehouses, commercial buildings, and process industries using pumps, fans, conveyor systems, mixers, or elevators.Q: When should I consider using the optional braking chopper or regenerative feedback units?

A: Optional braking choppers and regenerative units are recommended where rapid deceleration or energy recovery is required, such as in high-inertia load applications or for maximizing energy efficiency in systems that frequently stop and start.Q: Where can I find further details on current ratings, dimensions, or installation?

A: Individual model specifications, including weight, size, and current ratings, are provided in the product datasheet or can be requested from dealers, distributors, or the manufacturers technical support team.Q: What is the process for requesting a supply quotation or product sample?

A: To receive a quotation or request a product sample, contact your local dealer, authorized distributor, or reach out directly to the manufacturer. They will guide you through the process, provide pricing, and detail sample exchange and shipping policies.Q: How does the F5 Series enhance operational reliability and safety?

A: With integrated protection against over/under voltage, overcurrent, short circuit, and overtemperature, plus conformal-coated boards, the F5 Series safeguards equipment and ensures consistent operation even in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in KEB Drive Category

KEB COMBIVERT F5

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Comprehensive motor control, flexible I/O, overload protection, programmable logic functions

Supply Voltage : 400 V AC

Product Type : AC Drive / Drive Controller

Power Source : AC Mains

18 F5 KEB Drive

Price 140000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Overload protection, short circuit protection, parameter programming

Supply Voltage : 400 V AC

Product Type : KEB Drive

Power Source : Electrical

16 F5 KEB Drive

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Overload Protection, EMC Filter, Programmable Logic

Supply Voltage : 400 V

Product Type : KEB F5 Series Drive/Inverter

Power Source : AC Mains

2 PLY (Sheet) Cutter Machine

Minimum Order Quantity : 1 Unit

Features : Good Quality

Supply Voltage : 220240 Volt (v)

Product Type : Cutter Machine

Power Source : Electric

|

NCS Automations

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry