NC Cutter Machine For Corrugated Box Service And Repair

NC Cutter Machine For Corrugated Box Service And Repair Specification

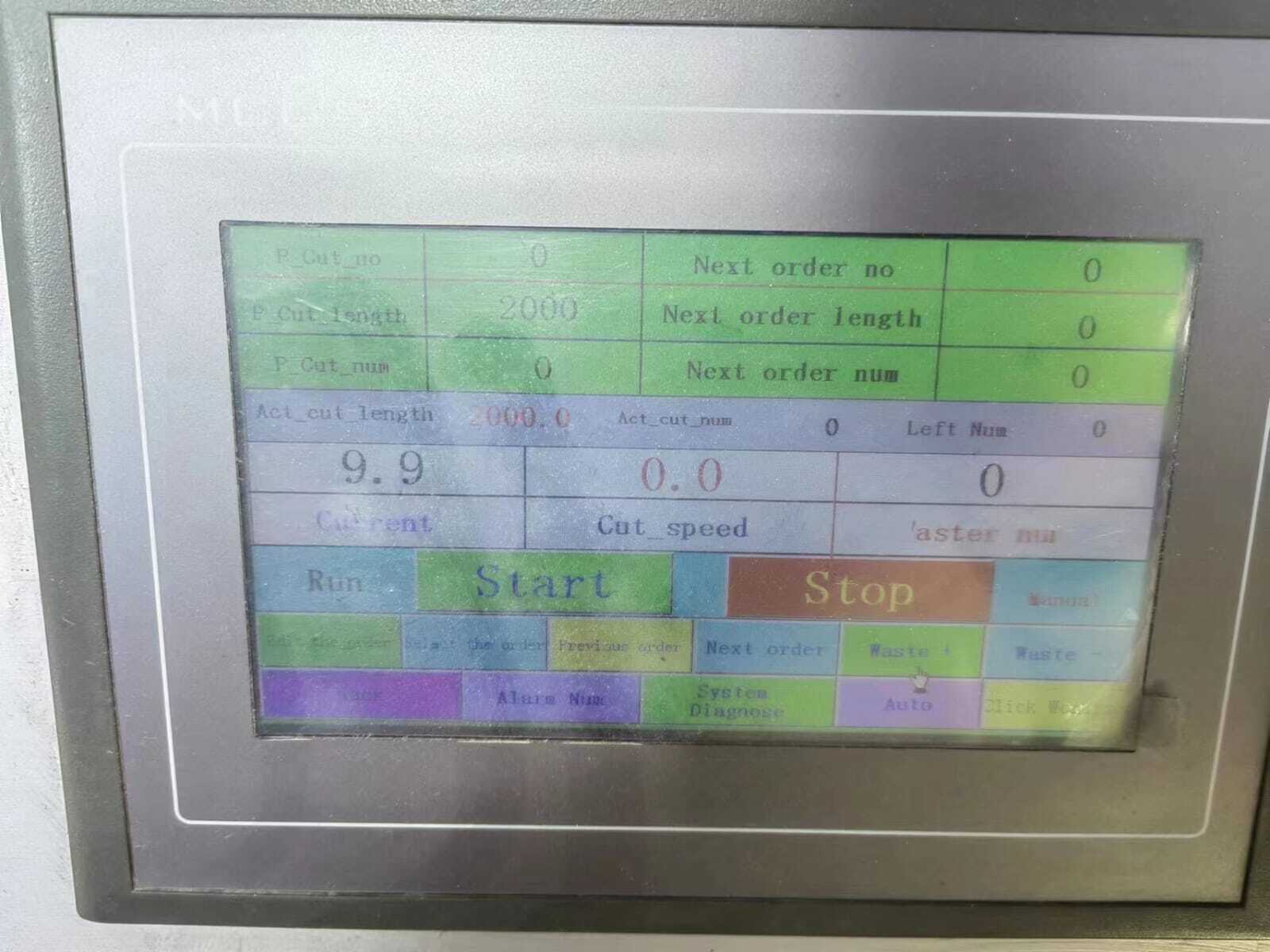

- Display Type

- Digital control display

- Resolution

- High cutting precision (up to 0.05 mm)

- Sensors Specification

- Integrated position and feed sensors

- Input

- Standard corrugated cardboard sheets

- Features

- Automatic feed, programmable length, rapid blade change, safety guard

- Usage

- For corrugated box service and repair workshops

- Power Supply

- Electric

- Operating Temperature

- 5C to 45C

- Processor Speed

- Industrial NC controller

- Components

- Cutter blade, NC control panel, motor, feed rollers

- Response Time

- Instant start and stop

- IP Rating

- IP20

- Output

- Accurately cut corrugated sheets

- Interface

- Touch button interface

- Power Source

- AC Electric

- Product Type

- NC Cutter Machine

- Application

- Corrugated box sheet cutting and trimming

- Rated Voltage

- 220V

- Supply Voltage

- 220V/50Hz

- Size

- Medium to Large (depends on model)

- Dimension (L*W*H)

- 2450 mm x 1050 mm x 1450 mm

- Function

- Cutting corrugated box sheets with high precision

- Color

- Blue and white

- Weight

- Approx. 350 kg

- Current Rating

- 10A

- Thickness

- 1 mm to 12 mm corrugated sheet

- Capacity

- 500-700 sheets per hour

- Frequency

- 50Hz

- Control System

- Numerical Control (NC)

- Compatible Material

- 3 Ply/5 Ply/7 Ply Corrugated Sheets

- Operator Required

- 1 skilled worker

- Noise Level

- <68 dB

- Drive Motor

- High torque AC motor (2 kW)

- Lubrication System

- Automatic oiling for moving parts

- Feed Type

- Automatic roller feed

- Installation

- Floor mounted

- Safety Features

- Emergency stop switch, overload protection

- Maintenance Requirement

- Low, routine check recommended every 3 months

- Blade Material

- Hardened steel

- Blade Life

- Up to 100,000 cuts (depending on sheet type)

About NC Cutter Machine For Corrugated Box Service And Repair

Engineered Excellence: Material Features & Applications

Crafted with premium hardened steel blades, the NC Cutter Machine delivers unmatched durability, handling 3 Ply, 5 Ply, and 7 Ply corrugated sheets up to 12 mm thick. It's predominantly used for precision cutting and trimming of corrugated box sheets, ensuring reliability and accuracy with every cut. Widely adopted in corrugated box service and repair workshops across India, this machine is preferred by skilled operators seeking efficient and safe sheet processing for diverse production needs.

Spectacular Export Reach and Timely Delivery

With a strong presence in the domestic market, our NC Cutter Machine enjoys high demand for its sale price advantage and reliable shipment processes. We ensure an exceptional supply ability of 15 units per month, with swift delivery times to bolster your operational continuity. Major export markets include Asia, Middle East, and Africa, where trusted distributors and dealers appreciate the machine's robust design and consistent cutting precision.

FAQ's of NC Cutter Machine For Corrugated Box Service And Repair:

Q: How does the NC Cutter Machine ensure accurate results for corrugated box sheets?

A: The NC Cutter Machine utilizes an industrial-grade NC control system and integrated sensors, offering high cutting precision up to 0.05 mm and automatic length programming for consistently accurate results.Q: What safety features are included in this machine?

A: It comes equipped with an emergency stop switch, overload protection, a safety guard, and automatic oiling, making operations reliably safe for one skilled operator.Q: When should routine maintenance checks be performed?

A: Routine maintenance is low and only recommended every three months to ensure optimal machine performance and extended blade life.Q: Where can this NC Cutter Machine be installed?

A: The machine is designed for floor-mounted installation and is suitable for corrugated box service and repair workshops across domestic and international markets.Q: What is the process of changing the blade on this cutter?

A: Thanks to the rapid blade change feature, operators can quickly and safely replace the hardened steel blade, minimizing downtime and maintaining the machine's cutting efficiency.Q: What are the benefits of choosing this NC Cutter Machine over manual cutting methods?

A: This machine delivers instant start and stop, automatic roller feeding, precise programmable cuts, and high throughput, making it vastly superior in productivity compared to manual operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in KEB Drive Category

KEB COMBIVERT F5

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : AC Mains

Size : Standard Compact

Supply Voltage : 400 V AC

Interface : RS232/RS485, CAN, Fieldbus (optional)

16 F5 KEB Drive

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : AC Mains

Size : Standard Modular Design

Supply Voltage : 400 V

Interface : RS232, RS485, CAN, Profibus (optional)

KEB Combivert F5 Series

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Mains AC

Size : Model dependent

Supply Voltage : 230V/400V

Interface : RS232/RS485, CANopen, Profibus; programmable digital/analog inputs

KEB Drive F5 Series

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Size : Model dependent, Compact Series

Supply Voltage : 230V / 400V

Interface : RS485 / CANopen / Profibus options

|

NCS Automations

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry